No more boring introductions, lets get started & understand how does a Wankel engine work & what exactly it is !

History :-

The first Wankel engine was developed by German engineer – Felix Wankel. Wankel received his first patent for the engine in 1929.

However, the Wankel engine design used today is designed by Hanns Dieter Paschke – which he adopted forming the modern engine !

Wankel engine :-

Wankel engine is an Internal combustion engine unlike the piston cylinder arrangement. This engine uses the eccentric rotor design which directly converts the pressure energy of gases into rotatory motion. While in the piston-cylinder arrangement, the linear motion of the piston is used to convert into rotatory motion of crankshaft.

Basically, in a simple way, the rotor revolve in housings shaped in a fat figure-of-eight.

Parts of a Wankel engine :-

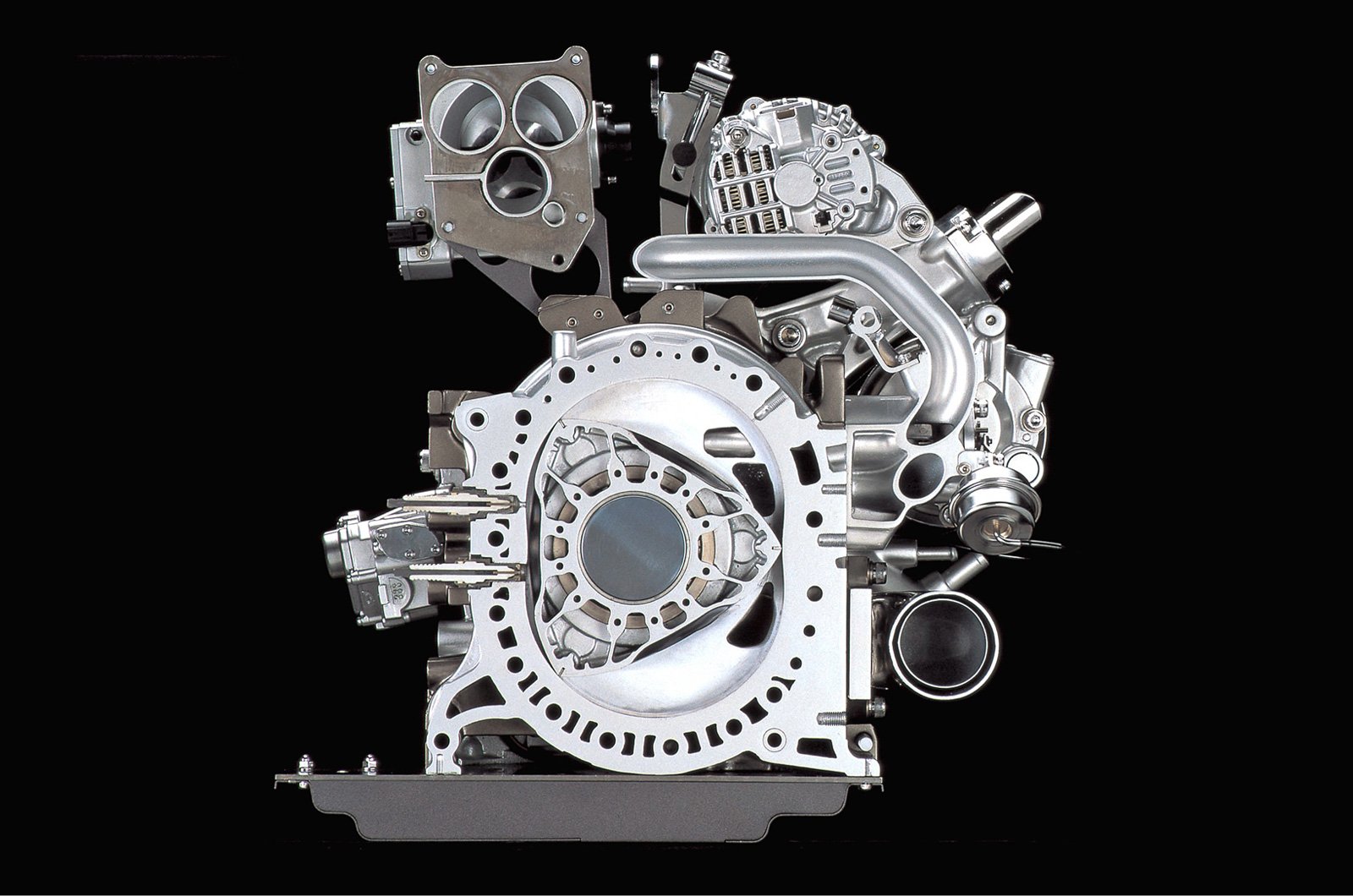

Rotor :- The rotor has three convex faces which acts like a piston. The 3 corners of rotor forms a seal to the outside of the combustion chamber. It also has internal gear teeth in the centre on one side. This allows the rotor to revolve around a fix shaft.

Housing :- The housing is epitrochoidal in shape(roughly oval). The housing is cleverly designed as the 3 tips or corners of the rotor always stay in contact with the housing. The intake and exhaust ports are located in the housing.

Inlet & exhaust ports :- The intake port lets fresh mixture enter into combustion chamber & the exhaust gases expel out through outlet/exhaust port.

Spark plug :- A spark plug delivers electric current to the combustion chamber which ignites the air-fuel mixture leading to abrupt expansion of gas.

Output shaft :- The output shaft has eccentric lobes mounted on it, which means they are offset from

centreline of the shaft. The rotor is not in pure rotation, but we need these eccentric lobes for pure rotation of the shaft.

Note :- The output shaft is a thing which can’t be explained completely in words. It is quite difficult to imagine it’s contribution in the working. this video link might help you to understand it.

Working :-

Intake :-

When a tip of the rotor passes the intake port, fresh mixture starts entering into the first chamber. The chamber draws fresh air until the second apex reaches the intake port & closes it. At the moment, fresh air-fuel mixture is sealed into first chamber & is being taken away for combustion.

Compression :-

The chamber one(between corner 1 to corner 2) containing the fresh charge gets compressed due to shape of the engine by the time it reaches to spark plug.

While this happens, a new mixture starts entering into the second chamber(between corner 2 to corner 3).

Combustion:-

When the spark plug ignites, the highly compressed mixture expands explosively. The pressure of expansion pushes the rotor in forward direction. This happens until the first corner passes through the exhaust port.

Exhaust :-

As the peak OR corner 1 passes exhaust port, the hot high pressure combustion gases are free to flow out of the port.

As the rotor continues to move, the volume of chamber goes on decreasing forcing the remaining gases out of port. By the time the corner 2 closes the exhaust port, corner 1 passes by the intake port repeating the cycle.

While the first chamber is discharging gases, the second chamber(between corner 2 to corner 3) is under compression. Simultaneously, chamber 3(between corner 3 to corner 1) is drawing fresh mixture.

This is the beauty of the engine – the four sequences of the four stroke cycle, which occur consecutively in a piston engine, occur simultaneously in the Wankel engine, producing power in a continuous stream.

Advantages :-

- Wankel engine has a very few moving parts; far less than 4 stroke piston engine. This makes the design of the engine simpler & the engine reliable.

- It is approximately 1/3rd of the size of the piston engines delivering same power output.

- Able to reach higher revolutions per minute than a piston engine.

- Wankel engine weighs almost 1/3rd of the weight of the piston engines delivering same power output. This leads to a higher power to weight ratio.

Disadvantages :-

- As each section has temperature differences, the material expansion of housing is different at different region. Therefore, the rotor is unable to completely seal the chamber in high temperature region sometimes.

- The combustion is slow as the combustion chamber is long, thin, and moving. Hence, there might be a possibility that the fresh charge discharges out without even burning.

- As unburnt fuel is in the exhaust stream, emissions requirements are difficult to meet.

7 comments on “How does a Wankel engine work ?”

The only production car I know that used a,Winkle engine was the Mazda RX7. Very fun car, with good pickup when you hit the gas. Mileage was, however, about the same as comparable cars. Smooth ride, but otherwise unremarkable.

Damn autocorrection. Wankle, not “winkle”–is “winkle” even part of the vernacular?

hehe Dr K! no problem !!! autocorrection suck sometimes ?

why wankel engine not used in cars like reciprocating engine what are the problems may i know please

hey there… as I said, emission requirements are very difficult to meet, also it has less fuel efficiency than reciprocating ones. Upon that the limiting factor is the design of the apex seals as you have to completely dismantle the engine !

what is top mileage on the rotory 13b engine i have owned 2 mazdarx7 one 1987 was able to get 207thousand b4 rebuild i am driving 1988 mazdarx7 it has 213thousand on it just beginning to smoke when starting thx

Thanks for the explanation in a nut shell!