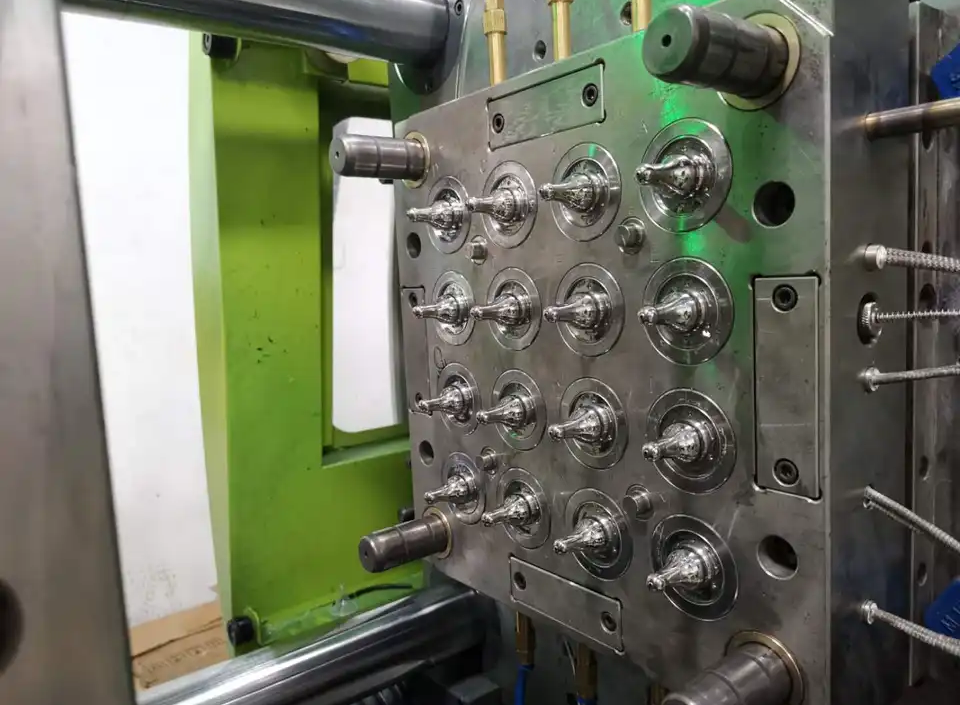

Injection molding is a rapid prototyping and manufacturing process applicable in the mass production of plastic parts. It is a six-step process that involves making a mold, clamping, injection, dwelling and cooling, and ejection. The injection mold is a unique component of the injection molding machine made from materials such as stainless steel and aluminum and comes in several designs divided into three categories: family mold, single cavity, and multi-cavity injection molds.

What are the benefits of using a multi-cavity mold and how does it differ from the other types of injection molds? This article discusses multi-cavity injection molds so that you can effectively use the right one for your job.

more “The Advantages of Multi-Cavity Injection Molds”