No more boring introductions today; I’ll just give you an idea about clutches & then directly straight to the topic – Types of clutches !

What are Clutches ?

Just for them who don’t have much of an idea, Clutch is an engaging & disengaging mechanical device which helps in transmitting torque/power produced by the engine.

They are used in every goddamn car, bike, trucks, locomotive engines & innumerous other vehicles & machines !

Each type has it’s own advantages & own field of application based on their torque/power transmitting capacity, their compactness & other design constraints!

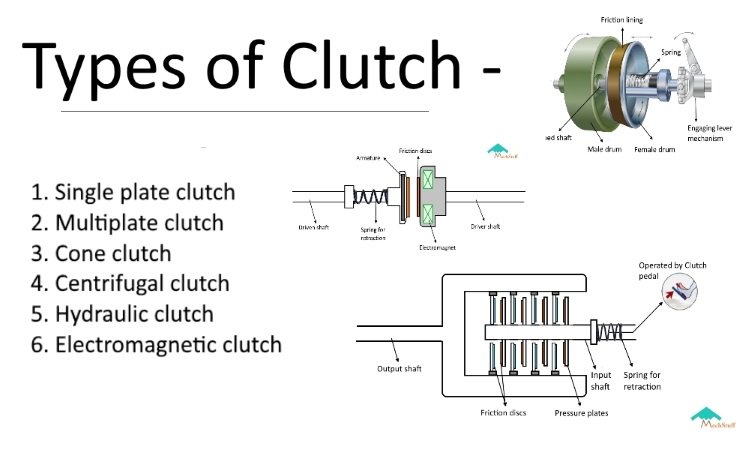

Types of Clutches :-

1. Single plate clutch

The single plate clutches have fewer parts comparatively & are very easy to understand. The device contains only 2 friction discs.

Torque transmission takes place when both of them come in contact with each other. One is bolted to the flywheel(gearbox, input shaft) while another is bolted to pressure plate & could be slide on a splined shaft. The pressure plate is connected to a pre-compressed spring(here diaphragm spring) which applies axial force on the other disc.

More the force, more the friction, more the torque transmitting capacity of the clutch.

These clutches had many limitations and hence it is highly unlikely to find them in any of the todays’ applications.

Thus there was an immediate requirement to design new types of clutches since they couldn’t provide adequate torque. Here is a complete detailed article on parts of clutch, working & why do we need them ?

Application – Machines and early vehicles where torque requirement is moderate.

2. Multi-plate clutch

Multi-plate clutches as the name suggests, consists of multiple plates or friction discs and work similarly in the above fashion. Multiple disc offer more area to be in contact with each other. More the number of plates more the torque transmitting capacity. Thus for same radius of friction disc used in single plate ones, multi-plate clutches transmit significantly high power.

They heat up quickly and this is one of their biggest disadvantage. Hence the whole clutch assembly containing plates is filled with oil to dissipate the heat faster.

Applications – They have a wide variety of applications in cars, trucks, locomotive engines & machines.

3. Cone clutch

Cone clutch consists of two drums- a male & a female. The male drum is attached with engine crankshaft and has inner friction lining while the female drum is mounted on a splined shaft and has outer friction lining.

When the clutch is engaged, the female cone gets inside the male one & they both start rotating together. The female cone is attached to a pre-compressed spring and has a similar apparatus as of single plate clutches.

The cone clutch can transmit higher torque than single plate clutches of same size because of relative more frictional area and wedging action.

The cone angle/semi-cone angle also plays an important role in providing the axial force. Generally, the semi cone angle is between 12º to 15º.

Applications – Cone clutches are are only found in racing cars and extreme off-road vehicles but more common in powerboats. Small cone clutches are used as synchronisers in transmission system & in limited slip differentials (LSD).

4. Centrifugal clutch

Centrifugal clutches are also called as automatic clutches since you don’t need a clutch pedal and they automatically engage.

The name itself says that the working of this clutch is based on centrifugal force. The construction and working both are simple.

There is a hub at the centre which is keyed with engine crankshaft. Multiple shoes are connected to this hub via springs and each shoe has its outer surface covered with friction material.

When the hub starts rotating, the shoes along with it also starts rotating. Any body performing rotational motion generates centrifugal force. The shoes are thrown outwards because of this force. As soon as the shoes touch the friction lining of the drum, the engine starts transmitting power to the drum i.e wheels.

The engagement of shoes with the drum takes place at a certain speed and this is a function of spring stiffness “k”.

Application– Mopeds & scooters like Honda Activa, Vespa etc.

5. Hydraulic clutch

Hydraulic clutches or fluid couplings are a part of a complex part called as torque converters which are used in cars with automatic transmission. These clutches consists of 2 different parts- pump and turbine & they both

have blades mounted at certain angle. The pump is attached to the driver shaft(flywheel) and turbine to the output shaft. As the pump starts rotating, the oil starts flowing outwards from centre due to centrifugal force.

The curved blades absorb the centrifugal energy and direct it towards the turbine blades. The design of both the blades is such that the flow of liquid sets both the parts in motion.

Application – Automatic transmissions

6. Electromagnetic clutch

What happens when you bring a magnet near a ferromagnetic material? I can hear you saying, “They attract each other, Jay, simple!” Exactly.. That’s it!

There is an armature on driven shaft and an electromagnet on the driver shaft. Current is supplied accordingly to the electromagnet when the clutch pedal is pushed or actuated. As the current is supplied, the electromagnet produces a magnetic field that attracts the armature. This generates a frictional force between both the friction plates when they come together. Within a short amount of time, the load is accelerated to to match the speed driving shaft(electromagnet).

Whenever the clutch has to be disengaged, electric supply is stopped & a spring retracts back the position of armature.

One of the biggest disadvantages of electromagnetic clutches is its initial high cost & rapid heating up.

Applications – Copy machines, factory automation, packaging machinery and some robots.

So, here we cover all the main types of clutches & I hoped you liked the article and I believe it was helpful! If you liked this, I’m sure you would like to explore the different types of brakes in automobiles(all animations)! If you have any questions or anything else, I would love to get back to you in comments section down below ! 😀